A double-acting Hydraulic cylinder is a cylinder in which the working fluid pressure acts alternately on both sides of the piston i.e. to and fro motion of Piston Rod. Double acting cylinders have a port at each end or each side of the cylinder, supplied with hydraulic fluid for both the retraction and extension.

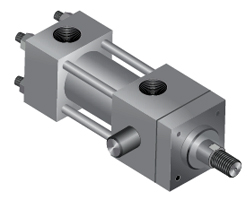

- Also available in adjustable stroke with cushioning

- Double-ended cylinder with female threading at both ends of rods

- Double-ended cylinder with hollow piston rod

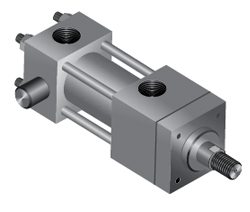

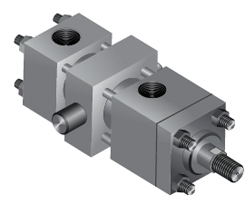

- Tandem-type double-ended cylinder also available as per requirement

Type of Mounting :

- Flange Mounting

- Foot Mounting

- Trunnion Mounting

- Tie Rod Extended Mounting

- Adjustable Stroke Cylinder Mounting

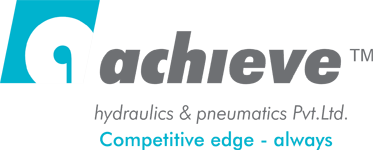

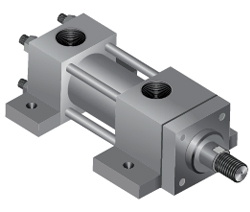

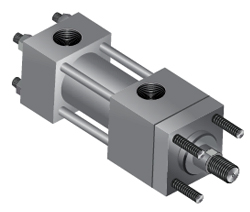

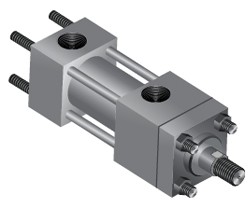

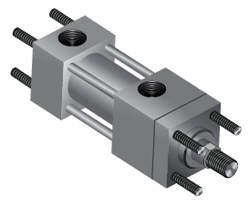

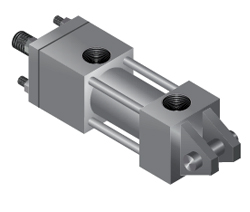

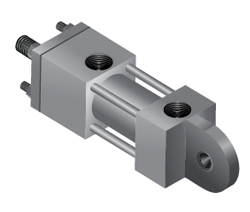

Tie rod type hydraulic cylinders use high strength threaded tie rods to hold the both end caps of the cylinder. It can sustain the tremendous hydraulic pressure.

This method of construction is most often seen in industrial applications.

Tie rod type cylinders can be completely disassembled for service and repair.

Heavy Duty Tie rod type Hydraulic cylinders (AHP STD series up to 200 Bar) Flange Mounting / Clevis Mounting

Head rectangular flange – ME5

Cap rectangular flange – ME6

Side lugs/ Foot Mounting – MS2

Head Trunnion Mounting – MT1

Cap Trunnion Mounting – MT2

Intermediate Fixed Trunnion Mounting – MT4

Tie rod extended head mounting- MX3

Tie rod extended cap mounting- MX2

Tie rod extended Both End

Cap Mounting Fixed Eye – MP3

Cap Mounting Fixed clevis – MP1

Cap Mounting Fixed Eye

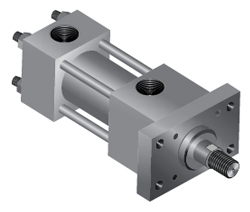

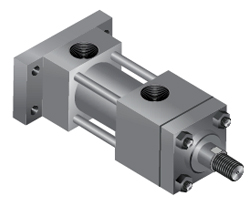

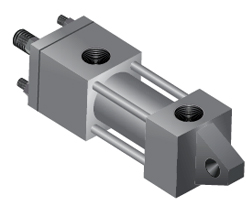

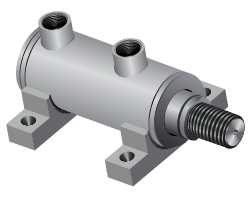

Welded Body Hydraulic Cylinders are designed for compact and reliable operation in heavy-duty applications. These cylinders have no tie rods-instead, the barrel is welded directly to the end caps, providing enhanced strength and leak-free performance. The ports are welded to the barrel, and the front rod gland is typically threaded or bolted to the cylinder body. This design allows easy removal of the piston rod assembly and rod seals for maintenance or service.

Mounting Options :

- Front Flange Mounting – ME5

- Side Lugs / Foot Mounting – MS2

- Rear Female Clevis Mounting – MP1

- Rear Male Clevis Mounting – MP3

- Both End Clevis Mounting

- Clevis with Bearing Mounting

- Trunnion Mounting

Hydraulic Cylinder Specifications :

| Parameter | Specification |

|---|---|

| Bore | Ø B mm |

| Stroke | < 1000 ±1 mm |

| Rod | Hard chrome plated Rod Ø mm, 25 μm thickness |

| Mounting | Front Rectangular Flange ISO ME5 Mounting |

| Working Pressure | 160 bar |

| Test Pressure | 210 bar |

| Design | Welded / Double Acting |

| Maximum Speed | 0.1 m/sec |

| Medium | Hydraulic Mineral Oil |

Front Rectangular Flange Mounting

AHP - WC - ME5 - Bore x Rod x Stroke

Rear Female Clevis Mounting - MP1

AHP - WC - MP1 - Bore x Rod x Stroke

Rear Male Clevis Mounting-MP3

AHP - WC - MP3 - Bore x Rod x Stroke

Rear Clevis with Spherical Bearing Mounting - MP5

Side Lugs Mounting - MS2

AHP - WC - MS2 -Bore x Rod x Stroke

Intermediate Trunnion Mounting - MT4

AHP - WC - MT4 - Bore x Rod x Stroke (min 100mm)

Rod End Eye

AHP - WC - Rod Eye -Bore x Rod x Stroke